Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

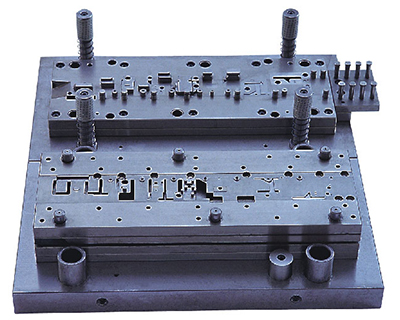

The surface processing method of stamping die is fast and processing quality is good, except for the cavity with inner sharp angle and the narrow and deep cavity, it can be competent in other aspects. In foreign countries has become the main process of stamping die processing, China is also in the active development. If the material is soft, the blanking clearance should be revised. The method is to repair the arc end or the slope of the end face of the punch, and use the blowing device, such as a vacuum cleaner, to add air to the blanking hole of the backing plate.

The stamping dies are worn out and the parts punched out have the edge of the edge, so the cutting edge needs to be repaired. Dalian stamping die is a special process equipment for processing materials (metal or non-metal) into parts (or semi-finished products) in cold stamping process, called cold stamping dies (commonly known as cold punching dies).

Stamping is a pressure processing method that uses pressure on the press to make the material separate or plastic deformation at room temperature, so as to get the required parts. The materials for the stamping die are steel, hard alloy, steel cemented carbide, zinc based alloy, low melting point alloy, aluminum bronze, polymer material and so on.

The production efficiency of the stamping process is high, and the operation is convenient, and it is easy to realize mechanization and automation. This is because stamping is done by stamping dies and punching equipment. The number of journeys of ordinary presses can reach dozens of times per minute, and the high speed pressure can reach hundreds or even more than a thousand times per minute, and each stamping stroke may get a punching piece. Stamping can produce parts with large size and complex shape, such as stopwatches from small to watch, large to automobile longitudinal beam, covering parts, etc., plus the cold deformation hardening effect of materials when stamping, the strength and rigidity of punching are all higher.