Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

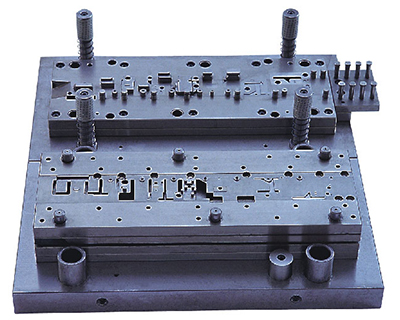

Dalian stamping die separation process has: blanking, punching, cutting, trimming, cutting and so on; forming process has: bending, circle, twisting, drawing, thinning, stretching, turning, flanging, stretching, swelling, undulating, expanding, contracting, spinning, calibration and so on.

Dies that separate materials along closed or open contours. Such as blanking die, punching die, cutting die, cutting die, trimming die, cutting die, etc. There should be no scratches, scratches and other defects on the machined surface of parts. No-load test shall be carried out after gear box assembly according to design and process regulations.

There should be no shock, noise, temperature rise and leakage in the test. The taper pin should be painted and inspected when assembling. The contact rate should not be less than 60% of the length of the taper pin, and should be evenly distributed. The outer ring of the bearing should be in good contact with the semi-circular hole of the open bearing seat and the bearing cover, and should be checked by painting.

The bearing seat should be in uniform contact with the bearing cover in the symmetrical center line 120 and the bearing cover should be in the symmetrical center line 90. When checking with a plug ruler in the above range, the 0.03mm plug ruler shall not be inserted into one third of the outer ring width. When the surface of alloy bearing liner is yellow, it is not allowed to use. No nucleation is allowed in the prescribed contact angle. The nucleation area outside the contact angle should not be greater than 10% of the total area of the non-contact area.