Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

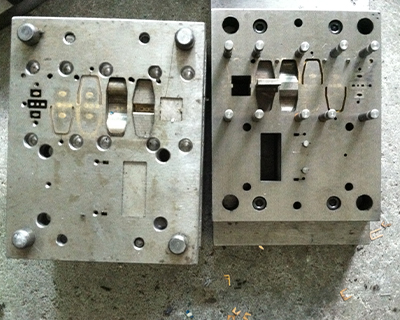

When the use of a pair of mold exceeded it's life-span, will replace the new mold, so the mold production is often repeated.Copying machining sometimes neither pattern in the mold production, also without the data, and according to the physical objects using the copying process.This requires a generic high precision, no deformation.Complex shape surface Some products such as automotive covering parts, aircraft parts, toys, household appliances, the shape of the surface is made up by a variety of surface, therefore, the mold cavity surface is complex.Mold material is excellent, the main material of high hardness mold is made of high quality alloy steel manufacturing, especially the high life of the mold, often using Crl2, CrWMn ledeburite steel manufacturing, etc.

1, the steel plate surface or a foreign body inside, with foreign body peeling, coil is scar on the same condition;

2, roller marks are attached to the rollers (foreign), foreign bodies caused by surface depth clearly.

3,Stamping partsProcessing irregular edge breakage, beyond material adverse beyond the rules;

4, due to sliding roller, foreign bodies in the coil back pressure after entering the bulge (foreign bodies fall disappear);

Stamping process for mainly according to classification, can be divided into separation process and forming process two kinds big.Separation process is also called the blanking, and its purpose is to make from the sheet metal stamping parts along the contour line must be separated, through actual use, with scratches (roll surface or different materials), foreign bodies in the coil back pressure after entering the bulge (foreign bodies fall disappear) and roll marks are attached to the rollers (foreign) is the most like to use.The solution is simple, foreign body disappear is the direct approach.At the same time guarantee the quality requirements of the separation section.Stamping with sheet metal surface and internal performance of stamping has great influence on the quality of the finished product, request stamping material thickness precision, uniform;Smooth surface, no spots, no scar, no scratch, no surface crack, etc.;Yield strength evenly, no obvious directivity;High uniform elongation;Showed low;Low strain hardening.