Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

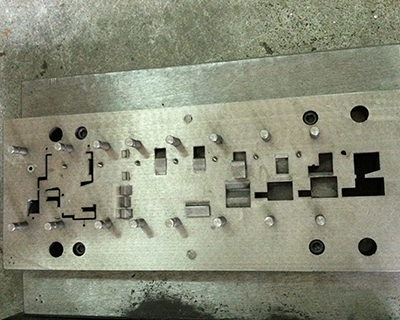

Dalian stamping parts did not feed the strip along the positioning correctly or did not guarantee the strip feeding according to a certain gap; punch and concave die because of long-term vibration impact and the central line changed, the axes did not coincide, resulting in one-sided burr. The position deviation between the inner hole and the outside of the workpiece is larger when the strip will be offset in the guide plate. During the bending process, when the billet slides along the surface of the die, it will be subject to friction resistance.

If the friction resistance difference between the two sides of the billet is large, the billet will deviate to the side with larger friction resistance. The bending line and the center line of two holes, where the bending height is less than the bending height, show the shape of opening out after bending, which can be divided into two categories: separation process and forming process. Separation process, also known as blanking, aims to separate stamping parts from sheet metal along a certain contour line.

At the same time, the quality requirement of separation section is guaranteed. The surface and intrinsic properties of sheet metal for stamping have a great influence on the quality of stamping products. It requires that the thickness of stamping materials be precise and uniform; the surface is smooth, without spots, scars, scratches and surface cracks; the yield strength is uniform and there is no obvious direction. With the increase of the pressure on the unloading plate, the material on the punch side is stretched (the compressive force tends to decrease), while the material on the die surface is compressed (the tensile force tends to decrease).

The reversal of stamping parts is caused by the tension of the material on the surface of the die. Therefore, when blanking, pressing and pressing material is the key point to prevent the blanking parts from turning over and twisting. In stamping, the discharging plate moves smoothly, and the material can be compressed. In the key forming part, the unloading plate must be made into an inlay structure to facilitate the solution of the grinding (pressing) loss caused by the long stamping of the unloading plate pressing part, but the material can not be compacted.

When the punch size is too large or too small (which may exceed the specifications) and there is a big difference with the punch size, besides considering the design size of forming convex and concave die, processing accuracy and blanking clearance, the following aspects should be considered to solve.