Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

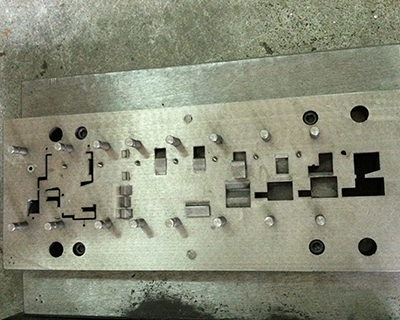

The common processing methods of Dalian mould processing are mainly casting method, cutting method and special processing method. In addition, according to the requirements of production process, the selected processing equipment is also different. Combining with many years'experience in injection mould processing, this paper gives a penetrating introduction to the compilation of efficient milling process for die parts, hoping to provide some help and reference for engineers and technicians.

In modern mold manufacturing, because of the increasingly complex design of the mold surface and the increasing proportion of free-form surface, higher requirements are put forward for the mold processing technology. In practice, in order to improve the efficiency of the mold processing, we can not blindly pursue high-speed processing. Sometimes, in order to save production costs and improve production efficiency, we must adopt efficient processing methods to make the mold more efficient. Some processing procedures can be completed efficiently on ordinary machine tools.

Processing procedures must be formulated according to the processing object and the actual production conditions of the enterprise, and the technology should be advanced. By calculating the constant cutting surface area and material removal rate, the main goal of inclined cutting (or arc cutting) and semi-finishing is to make the contour of the workpiece smooth and the surface finishing allowance uniform, which is particularly important for tool steel dies.

The semi-finishing strategy should be optimized to ensure that the workpiece surface after semi-finishing has a uniform residual machining allowance. The optimization process includes the calculation of contour after rough machining, the calculation of large residual machining allowance, the determination of large allowable machining allowance, and the finishing strategy of the die depends on the contact point between the tool and the workpiece.

The contact point between the tool and the workpiece varies with the change of the slope of the surface and the effective radius of the tool. For complex surface processing which is composed of multiple surfaces, continuous processing should be carried out in one process as far as possible, instead of processing each surface separately, so as to reduce the number of times of tool lifting and cutting.