Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

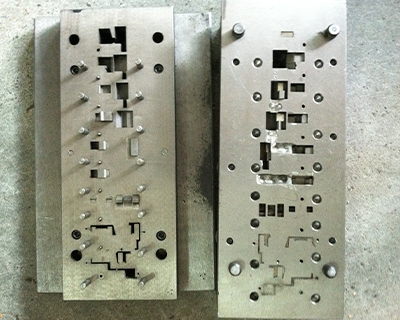

n order to improve the strength of stamping die, stamping die making Dalian the last procedure needs to be processed on the surface of the mould, to eliminate small cracks on the mold surface, prevent under press strong impact in the process of crack damage amplification of stamping die. The common grinding equipments are surface grinder, internal and external grinding machine, tool grinder.

In order to ensure accuracy, CNC machining is generally used. According to the different parts of the shape to choose the right type of grinder, plate type parts using surface grinder, cambered surface and rotary surface parts using internal or external grinder or tool grinder. Since the reform and opening up, with the rapid development of the national economy, the market demand for the mold has been increasing.

In recent years, the mold industry has been rapid development in the growth rate of about 15% of all components of the system mold industrial enterprises has undergone tremendous changes, in addition to state-owned professional mold factory, collective, joint ventures and private development has been rapid.

Due to geographical proximity, the industrial cluster of automotive panel die to form a highly refined, with professional division and cooperation system closely, in the social division of labor advantage of SMEs are not economical scale defects, effectively reduces the production cost and transaction cost.

The surface quality of stamping die parts is mainly caused by excessive burr. The cause of burr is too large, the first is the die edge wear, should be re grinding mold (hereinafter), to ensure that the edge is sharp. Secondly, the intermittence of the convex and concave die is unreasonable, and the clearance of the ambassador side is mostly the wiping band. The gap is too small, and the two shear plane will appear. If the material hardness is too high, the material or the gap should be replaced. A mold is a tool for forming objects. This tool is made up of various parts, and different molds are made up of different parts. The shape of the material is mainly processed by the change of the physical state of the forming material.