Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

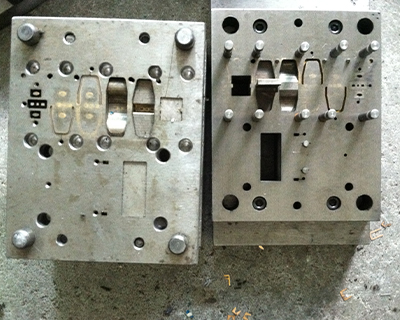

Mold according to different shapes. The die is divided into upper and lower die modes, and is completed by the integrated process of car, planer, milling, etching and electrical discharge. The shape and size of the pit are consistent with that of the product. Because the wax mold is mainly used for industrial wax press type, so the use of melting point is not high, hardness is not high, low demand, cheaper prices, lighter aluminum alloy material mold.

Dalian stamping parts must be simple shape, reasonable structure, in order to simplify the mould structure, the number of processes, stamping process is to use the fewest and simplest complete machining of the part, reduce the processing and other methods, and is conducive to stamping operation, to facilitate the organization of mechanized and automated production, to improve labor productivity.

The main points of the lathe equipment for stamping parts are as follows: don't open the cuffs and put on tight protective clothing. Wear protective caps for long hair and wear gloves when handling. The chuck and disc must have a reliable bolt, tighten before use; the taper shaft chuck shall be fitted with a tie rod. Before operation, we must check the working condition of the lathe, find out the problems in time, and clamp the workpiece and tool to be fastened. Clamping chuck, holding the workpiece of the dial, the projecting part of the heart-shaped clamp rod is used to avoid the protective cover, other parts of the body and clothes in linesabout. If there is no protective cover, the operation should pay attention to spacing, do not approach.

The stamping process has the advantages of high production efficiency, convenient operation, and easy realization of mechanization and automation. This is because the stamping dies and stamping equipment rely on to complete the processing, ordinary press trips per minute up to dozens of times, high pressure per minute up to hundreds or even thousands of times, and each press stroke may get a red piece.

Stamping processing size range is large, complicated shape parts, such as a small clock stopwatch, large car rails panels, plus the stamping material hardening effect of cold deformation, punching strength and stiffness were higher.