Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

When stamping dies begin to make plastic moulds in Dalian, reasonable control of preformed back pressure at first should help to discharge all gases in plastics and reduce the chance of burning products. The performance of the low back pressure plastic decided by the processing and related parameters, usually 015- 115 MPa, with high viscosity and poor thermal stability of plastics, should adopt the screw speed slower and lower pre plastic back pressure, some of the viscosity difference but good thermal stability of plastic, can be used to improve the pre plastic back screw speed and higher, but should prevent the phenomenon of melting casting.

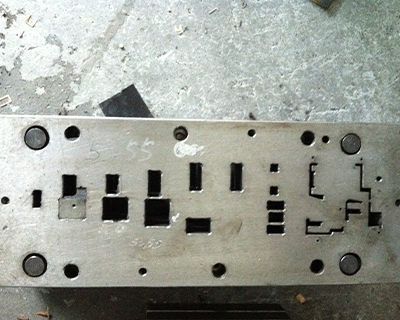

Stamping is a pressure processing method that uses pressure on the press to make the material separate or plastic deformation at room temperature, so as to get the required parts. The materials for the stamping die are steel, hard alloy, steel cemented carbide, zinc based alloy, low melting point alloy, aluminum bronze, polymer material and so on.

When the working temperature of the mold is higher, the hardness and strength will decrease, which causes the die early wear or plastic deformation to fail. Therefore, the mold material should have high anti tempering stability, so as to ensure that the mould has high hardness and strength at working temperature.

In general, the manufacture of mould must be made by forging, cutting, heat treatment and so on. In order to ensure mold quality and reduce production cost, the material should have good Forgability, machinability, hardenability, hardenability and grindability. It should also have small oxidation, decarburization sensitivity and quenching deformation and cracking tendency.

The average price gap between the import and export of die and mold in China is decreasing, which also reflects the improvement of the overall level of the mould industry and the progress of science and technology in our country. It is obvious that the mould industry of our country has made great progress and a certain effect after many years of continuous efforts. It is believed that the future of the domestic mold industry will go to a higher level.