Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

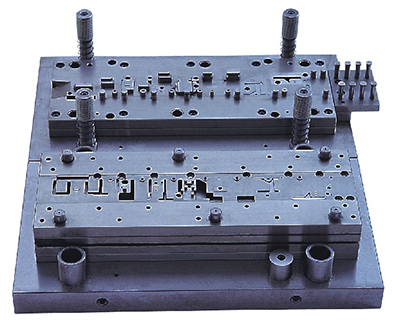

Characteristics of deep excavation of Dalian stamping die

There are many factors that affect the deformation and cracking of the hot stamping die, which are related to the original structure, the chemical composition of the steel, the structure and shape of the parts, the size of the section, the heat treatment process and so on. Cracking can often be prevented, but heat treatment is always difficult to avoid. After the mold part is removed from the coolant, it should not stay in the air for a long time. Low temperature temper brittleness and high temperature temper brittleness should be avoided during tempering. For some of the precision requirements of the mold parts, after quenching using multiple tempering treatment, in order to eliminate the internal stress, reduce deformation, to avoid cracking tendency. Mold parts into the coolant, should be appropriate to rotate, and the rotation direction of change, so that the parts to maintain a uniform cooling rate, can significantly reduce the deformation and prevent cracking tendency.

The stamping die is a kind of special process equipment, which is called cold stamping die, which is a kind of special processing equipment, which is made of metal or nonmetal. The utility model relates to a press processing method, which is used at room temperature, and the pressure is applied to the material which is installed on the press to cause the separation or plastic deformation to obtain the required parts. In recent years, the overall technical level of advanced precision stamping mould to improve quickly, the level of mold technology, manufacturing precision, service life and manufacturing cycle performance index has been significantly improved, a considerable part of the overall level of high quality mold has reached the level of similar international mould. Such as the company's production of air conditioner fin progressive die life of up to 500 million times, production scale and technology development in the domestic leading position.