Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

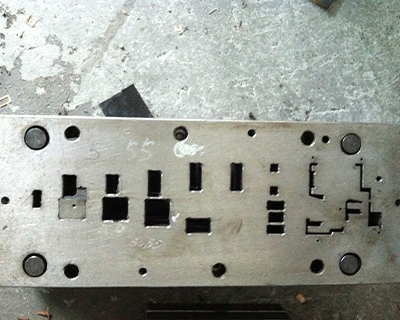

Enhance the technical strength of Dalian stamping die

In accordance with the traditional production methods of stamping die surface processing are used: rough machining, semi finishing finishing. Go to the general assembly, the first bench with sand wheel machine, and then use coarse polishing stone, then fine stone light repair. This often results in two problems. Fine processing technology on the basis of inheriting the traditional processing methods have been greatly improved, the quality of the surface has been greatly improved, can not be studied with the pressure on the pieces, trimming edge clearance rate of more than 75%. Reduce grinding fitter assembly time up to 30% to 40%, greatly improve the quality and efficiency. If the gap is too large, the waste will be rough, undulating fracture surface and a narrow bright band. The larger the gap, the greater the angle between the fracture surface and the zone. If the gap is too small, the waste will present a small angle fracture surface and a wide bright band region.

The stamping die should be silvery white and cold gas in vacuum carburizing after released, if released when the brightness component deterioration reasons may be: the furnace produced a larger leakage; vacuum quenching oil mixed with more air; cooling gas (e.g. nitrogen) is not high purity, which contains more oxygen cylinder oil; more into the vacuum quenching medium. For this type of stamping die, the design should be made to reduce the length of the small convex mold to increase the strength, at the same time, should also be used to guide the way to strengthen the small convex mold protection. In addition, in stamping die design, should give full consideration to the factors of fixed form, method of punch die and guide form, pressure center and upper and lower rigidity of the formwork etc..