Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

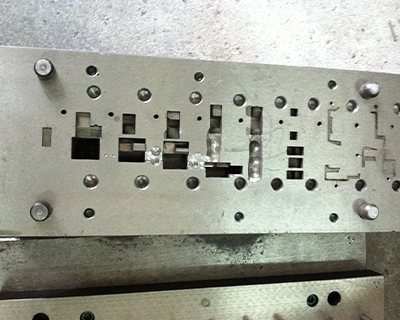

Dalian stamping die mold produced by fault analysis!

Stamping die at work to withstand the shock, vibration, friction, high pressure and tensile, bend torsion load, even working in high temperatures (e.g., cold extrusion), complex working conditions, easy to wear, fatigue, fracture, deformation phenomenon. As a result, the requirement of the working parts of the mold material is higher than common parts. Carbon tool steel in the mold is widely applied for T8A and T10A advantages for processing performance is good, price is cheap. But hardenability and red hardness, heat treatment deformation, bearing capacity is low. Carbide hardness and wear resistance is higher than any other types of steel, but the bending strength and toughness is poor. Used for mould cobalt tungsten carbide is class, the impact is small and require high wear resistance of the mold, can choose a lower cobalt content of carbide. The impact of mold, can choose containing a high percentage of cobalt cemented carbide.

Mold design and manufacturing technology level of high and low, is the measure of a country manufacturing level one of the important marks of on any account, to a great extent, decides the quality of products, and new product development capability. Stamping die is an essential part of stamping production technology and equipment, is a technology-intensive products. Stamping parts quality, production efficiency and production cost, etc., and mold design and manufacturing has a direct relationship. This kind of mould application widely, structure is simple, easy manufacture, but the production efficiency is low. In order to improve productivity, can be more than stamping process, such as blanking, deep drawing, punching and trimming arranged on a mold, to make blank on a workstation multichannel stamping process, this mould is called composite modulus.