Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

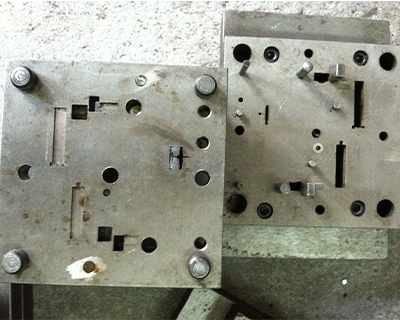

Rough machining, semi finish machining and finish machining, and sometimes even super finishing (mostly for high speed cutting applications). Residual milling is, of course, prepared for finish machining after semi finish machining. It is very important that each process should strive to leave a uniform distribution margin for the next process.

Mold is the processing of raw materials, giving raw materials to complete configuration and precise size of the processing tools, mainly for efficient, mass production of industrial products in the relevant parts. With the development of modern industry, Dalian mold processing is applied more and more widely, in the automotive, electronics, instrumentation, home appliances, aerospace, building materials, electrical and communications equipment and other products, about 60%-80% parts depend on the mold processing, so it is called "the mother of industry".

The importance of plastic mold processing factory in such market conditions become more and more strong, the market of plastic mold products demand utility are also increasing, so far the plastic mold processing factory to drive the rapid development of the industry in the future will become better and better, so all industries can use.

At present, processing automation has already applied in the mold production can be divided into three kinds, namely a plurality of interchangeable workbench CNC machine components production line, production line and integrated machining center. The first production line includes many machine tools, such as bottom machining, rough milling, fine milling, etc..

As the machine tool is multi working table, the workpiece does not need to re install the card, so the processing efficiency is very high. Because the mold is molding tool, so the requirements of precise size, smooth surface, reasonable structure, high production efficiency and easy automation; and easy manufacture, low cost, high service life; you must also take into account the design meets the process requirements, economic and reasonable etc..