Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

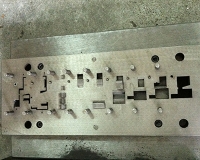

Improve the processing performance of dalian mold processing equipment

1. The high dynamic accuracy. Machine tool manufacturing enterprise is introduced the static properties (such as repeated positioning accuracy, linear feed rate) in the mold 3 d type surface processing, can't reflect the actual processing. Of 3 d surface mold precision machining, puts forward the requirement of high precision dynamic performance, high speed and high precision but also in the machine tool of high rigidity, high thermal stability, high reliability, and quality control system of combination become possible.

2. The molding parts of increasingly large and parts of the high productivity requirements more than a mold cavity, the increasingly large mould, large-tonnage big mould can reach 100 tons, a die hundreds, thousands of cavity, the cavity mould processing equipment large workbench, increasing Y Z axis stroke, large bearing, high rigidity, high consistency.

3. For complex cavity and multifunctional composite mould, as parts of complicated shape, must improve the level of mould design and manufacture of a variety of groove, a variety of material in a mold forming or assemble components of multifunctional composite mould, requires large amount of processing programming procedures, with comprehensive Gao Shenkong cavity cutting ability and high stability, improve the processing difficulty.

4. Mould processing compound, high efficiency for the fine machining equipment of more attention. Of high speed milling machining high hardened steel, stable machining, cutting force is small, the workpiece temperature deformation, and many other advantages to make mold enterprise of high speed machining is becoming more and more attention.

5. The processing technology and the technique of green products will be within the scope of enterprises into consideration when purchasing equipment of electric machine radiation, medium selection will be safe, steel impact factors, electric fire steel milling technology can get mould processing areas in the future. High and new technology improvement and creation is any industry must and must do, because the only technology can be in the field of industry inner ring good belongs to own a piece of land, and mould industry in our country is moving in this direction.

6. Mould processing of die steel materials, high hardness, request mould processing equipment with high thermal stability, reliability.