Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Trend continuously optimize metal stamping mold and die industry, will be the potential do not have to!

Domestic stamping die industry is increasingly pursued the world's advanced level, and constantly narrowing the technology gap with developed countries, many domestic precision stamping die on the main performance has to be able to compete with imported products, industry overall level significantly improve, not only realize the import substitution, there are quite a number of production exported to the United States, Japan and other developed countries and regions.Core tip: domestic hardwareStamping partsIndustry layout adjustment, is the natural trend of economic development, the eastern region after years of technology, talent and capital accumulation, will gradually transition to high-end products production base

Metal stamping parts industry layout adjustment, is the natural trend of economic development, the eastern region after years of technology, talent and capital accumulation, will gradually transition to high-end products production base, and emerging centers will undertake a part of the perfection of production.High carbon high chromium or chromium in tool steel, medium carbon alloy steel, high speed steel and the matrix steel and carbide, steel bonded carbide, etc.In the next few years, the domestic stamping mold industry will achieve tremendous, backbone impetus of the development of domestic die industry, improve industry overall technical level to a higher level of development.

Although domestic precision stamping die and there is still a big gap between the developed countries, but in accordance with the present domestic the development of the industry, mold industry to further enhance the level of the technique and technology and the division of labor is reasonable, broke the past a single product, regional homogeneity serious situation, also provides a step in the development of mould industry in China.The types of commonly used mold working parts material: low carbon tool steel, alloy tool steel, would considerably increase the ability of domestic enterprises to grasp the market, so as to achieve in the next five to ten years industry scale and technical level of dual qualitative change.

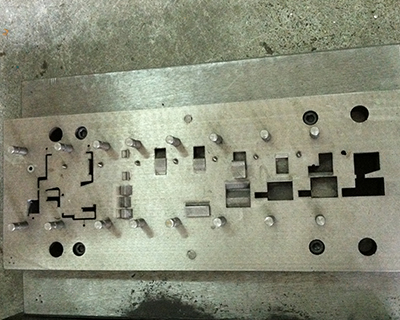

Dalian stamping die, using all kinds of metal materials and nonmetal materials, mainly carbon steel, alloy steel, cast iron, cast steel, hard alloy, low melting point alloy, zinc base alloy, aluminum bronze, synthetic resin, polyurethane rubber, plastic, laminated birch wood, etc.To mold parts and auxiliary structures of other process structures of parts material, will increase accordingly.When not in quantities, should be appropriate to relax on the properties of the material requirements, in order to reduce costs.

Manufacturing stamping die steel, hard alloy, with the material of steel bonded carbide, zinc base alloy, low melting point alloy, aluminum bronze, polymer materials, and so on.Manufacturing stamping die for the most part of material is given priority to with steel, when stamping production batch is very big, mold working parts of convex die and concave die material selection should be high quality, good abrasion resistance steel.

Stamping die belongs to cold work die steel materials used, is are big, wide use of surface, most types of steel.The main performance requirements for strength, toughness, wear resistance.Cold work die steel in high alloy steel is the development trend of D2 (equivalent to our country Cr12MoV) based on performance, divided into two branches: one is reduce the amount of carbon and alloy elements, improve the distribution of carbide in steel evenness, prominent improve the toughness of the die.