Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Stamping company introduction to stamping mould design experience

Core tip: the concept of stamping die stamping die, also known as punching die, metal molds, metal stamping mold, meaning almost are the same.Refers to the use of fixed to the press or pressure on the mould the concept of gold stamping die

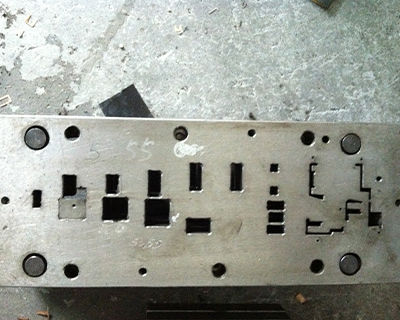

Stamping die, also known as punching die, metal molds, metal stamping mold, meaning almost are the same.Refers to the use of the fixed mold on hot press or pressure of sheet metal or nonmetal a certain pressure, make the material produces separation or forming, thereby gaining a certain size requirements, the appearance quality of qualified parts of pressure processing method.Mold is divided into a lot of kinds, I here I mainly for the familiar metal stamping mould.

throughMould processingOut of the product, size, appearance is basic and same, it's not a big difference, because can rapid prototyping, high production efficiency, product quality is stable, the precision meets the requirements, high material utilization, simple operation, low labor intensity of workers, technical requirements of operating workers is not high, average person just came in, followed the others learn operation for a day or two, will soon be able to get started, some don't even need a day or two, a few minutes to learn.If is a main hand production line, to learn to operate punching machine, feeder, leveling machine, die set down the mould and so on, are very simple live, there is strength, willing to bear hardships and stand hard work.

Mould processing refers to the processing, molding and blocking tools in addition to including shearing die and die cutting mould.Usually, mould has the upper die and lower die of two parts.Place the plate between the upper and lower mould, realize the material under the role of the press forming, when the press to open, will obtain the determined by the mold shape workpiece or eliminate waste.

1. The forging die

2. The plastic injection mold, injection mold, extrusion mold, mold

(3) metal stamping die, progressive dies, single die, compound die, stretching mold

4. Rubber mold

5. Powder metallurgy mold

6. Die casting mould

Usually pay attention to safety don't put any mold inside things inside, wrench, scissors, and other tools such as don't put inside the mold, mold repair to repair after mold (professional term: mold repair), you will like before, to see if they forget things inside the mold, general mold repair is, of course, won't make such a mistake, but you also need to pay attention to.

To mold the line, or to deal with the mould often accident prone, new people into the factory special attention should be paid to these security matters.

The structure of stamping die is introduced

The structure of stamping die, die structure, die structure is the same, according to different product features and design the corresponding mold demand, different mould structure, its function is different also, production of products is also different, generally have simple, has a complex.But no matter how the structure is complex, its basic structure is the same, nothing more is several templates, into pieces and standard parts.Don't break the mold, or put the body where hands hurt, do this remember pay attention to safety, carelessly die inside thing forgot to take it out, punch down it may break the mold, one thousand the contents if fly out?, people will be likely to get hurt.

Mould is commonly by a number of templates and parts (we call it into the block, or a child) and standard parts assembled.