Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

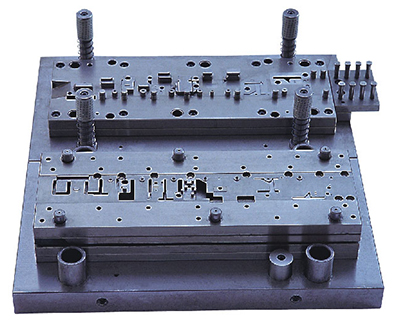

What are the classification of the stamping die ?

Stamping dieA lot of, in the form of die also in accordance with the nature of work, die structure, die materials three aspects to classification.

According to the processing of product classification method

According to the difference of the product processing method, can be divided into moulds shearing die, bending die, drawing die, five categories, such as forming mold and the compression mould.

A. compression mold: is the use of powerful pressure, the metal flowing deformation of hair embryo into required shape, its types are extrusion die, embossing dies, stamping die, the die pressure

B. punching and shearing dies, is a shearing action to complete the work, commonly used in the form of cutting die, blanking die, punching die, the trimming die, the whole edge die cutting, hole punching and die cutting mould.

C. and drawing die, drawing die is made a bottom seamless container MAO embryo on the plane.

D. forming mold: refers to through a variety of local deformation method to change the shape of hair embryo, its form has raised a forming die, roll edge forming die, necking forming die, hole flange forming die, flange forming die.

。

E. bending die: is the smooth hair embryo bent into the shape of an Angle, depending on the shape of the parts, precision, and the amount of production, but there are many different forms of mold, such as ordinary bending die, bending die CAM, crimping die seam, circular arc bending die, bending die and die, etc.

According to the classification process characteristics

A. forming die is blank or semi-finished workpiece according to the figure of convex and concave die shapes directly copy shape, and material itself only produce local plastic deformation of the mold.Such as bulging die, reducing die, flaring die, ups and downs, forming die, flanging die, plastic mould, etc.

B. riveting die is borrow outside force to participate in way of parts according to certain order and connection or lap together, to form a whole

C. blanking die along a closed or open the contour line of separation material of mold.Such as blanking die, punching die, die cut mold, cut, blanking die, die cutting, etc.

D. bending die making sheet metal blank or other come along a straight line (curved line) to produce bending deformation, thereby gaining a certain Angle and shape of the workpiece in the mold.

E. deep drawing die is made the sheet metal blank opening hollow, hollow or make a further change shape and size of the mold.

According to process combination degree classification

A. single process model in a press tour, just completed a die stamping process.

B. progressive die (also known as continuous mode) on the blank into the direction of, have two or more stations, in a press trip, in a different location on the successive completed two or more than two servings of stamping process the mold.

C. transfer mode combines the characteristics of the progressive die and mould single process, using the mechanical transmission system, mould rapid transfer is achieved, and can greatly improve the production efficiency, reduce the production cost of products, saving material cost, and quality is stable and reliable.

D. composite modulus is only one station, in a press trip, in the same station at the same time to complete two or more than two servings of stamping process the mold.

Dalian stampingMould processingCompany to design and production of stamping die, forging die, simple injection mould is given priority to, has a complete and scientific quality management system.If you have aStamping partsThe demand of the processing, mold processing, welcome to give us a call.