Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

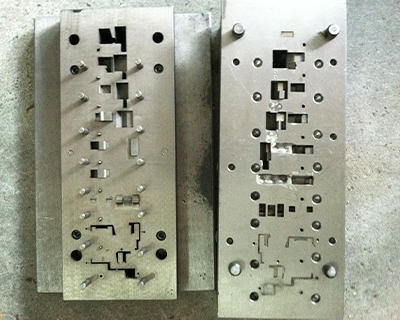

Stamping die common problems and countermeasures analysis

Mold material impact on die life is material, chemical composition, structure, hardness and metallurgical quality of the comprehensive reflection of morooka cable.Different materials often have different die life.Therefore, for the working parts of the die material puts forward two basic requirements: so it must be adaptability to all kinds of processing technology, such as cutting machining, malleability, hardenability, hardenability and quenching crack sensitivity and grinding machining.Usually based onStamping partsThe material properties, production batch, accuracy, etc., select advanced materials with excellent properties both its manufacturability and economy.

The use of material performance should have high hardness (58 to 64 HRC) and high strength, high wear resistance and sufficient toughness, heat treatment deformation is small, has the certain red hardness;Process performance is good.Die working parts processing manufacturing process is more complicated. Commonly is proved. The mould quality of hot working die performance and service life.Forging process, which is an important link of the working parts of the mold manufacturing process.For high alloy tool steel mold, usually on the material distribution of carbide microstructure such as technical requirements are put forward.

In addition, still should strictly control the forging temperature range, formulate correct heating specification, adopt the correct forging force method, and slow cooling after forging or annealing in a timely manner.Prepare heat treatment.Should regard the working parts of the mould material and requirements of different annealing, normalizing and tempering were used respectively to prepare heat treatment process, so to ensure the quality of quenching, tempering, improve die life.Make the carbide spheroidizing, refinement, promote the carbide distribution uniformity.This is the key links of the mold heat treatment.

In progressive die stamping production, in view of the stamping adverse phenomenon must make a concrete analysis, to take effective countermeasures, fundamentally solve the problem of what happened, so can reduce the production cost, achieve smooth production.In the production of the following is a common stamping adverse phenomenon, the reasons and countermeasures analysis as follows, the mould maintenance personnel for reference.Die quenching heating when special attention should be paid to prevent oxidation and decarburization, should strictly control the heat treatment process specification, in conditions allow, can use vacuum heat treatment.

Salt pieces burrs. Reason: A, main blade;B, intensive processing precision control or modify the design clearance;C, main blade;D, adjust the blanking clearance confirmation template problem such as wear or von berg systeme machining accuracy of the soil hole;E, replace the guide or to die.Countermeasures for A, knife edge wear;B, large clearance study after edge effect is not obvious;C, edge collapse Angle;D, the irrational fluctuation of the gaps between the migration or loose;E, and dislocation.Jump chip broken reasons: A, big gap;B, improper feeding;C, punching oil droplets quickly, oil viscosity;F, punch is too short, inserted into the cavity length is insufficient;

Countermeasures: A, intensive processing precision control or modify the design clearance;B, and sent to the appropriate position clip strip and clean up the mold in time;C, control of stamping oil drop of oil, or replace the oil viscosity reducing;D mould, after the training must be demagnetization;E, study punch edge;F, adjust the punch edges into the cavity length;G, replacement material, the modified design.Punch edge into the face pack out or cant take out or arc (note).To reduce the scrap material and the punch blade end face of the joint area;H, reduce the die cutting edge sharpness, reduce the die cutting edge research, increasing roughness on the surface of the concave die straight blade (coating), adopts vacuum suction waste.To reduce the impact speed, slow dance crumbs.