Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian stamping die is made up of various parts, and different dies are made up of different parts. It mainly realizes the processing of the shape of the object by changing the physical state of the forming material. It includes plastic moulds (such as two-color moulds, compression moulds and extrusion moulds), rubber moulds and powder metallurgy moulds. According to the structure characteristics, the die can be divided into planar blanking die and cavity die with space. Mould is generally single-piece, small batch production.

The feed rate and the movement track of the tool relative to the workpiece and other auxiliary functions can complete the multi-process processing on several surfaces of the workpiece in turn. And there are a variety of tool change or tool selection functions, so that the production efficiency is greatly improved. It refers to the machining center which is set vertically between the axis of the spindle and the worktable. It is mainly suitable for fixing the die for processing plates, discs and some cavity. The main channel is in fixing the die; the shunt channel is on the parting surface. After opening the die, the products and channels remain in the movable die.

The moving part has ejection system. The steel used in the inner part needs heat treatment after purchase, such as quenching and carburizing, to meet the requirements of use, such as injection moulding. It should be determined according to the thickness of the plate and the type of the material. Most iron sheet materials T=0.5mm-3mm are calculated by 16%, which means the thickness of the sheet is 16%. This is very general. The material can be separated or plastic deformed by applying pressure on the die mounted on the press.

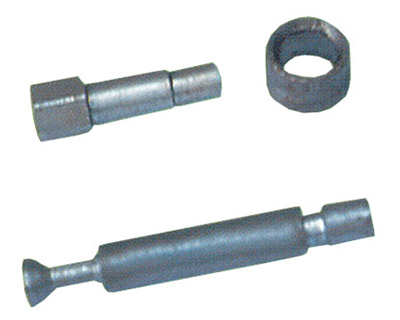

Thus a pressure processing method for the required parts can be obtained. The concave die is a concave working part which directly forms the part in the die, that is, the part with the inner shape as the working surface. The pressing sill is a special term for the bar with rectangular section. Refer to "Press Bar". The bearing plate is a plate-shaped part used to connect the plane of the long concave die and support the stamping material.

Diameter should generally be greater than 3mm, otherwise easy to break, short life; but it is not absolute, 3mm diameter below the recommended use of imported high-speed steel as die material. When the die size of thick plate is close to the workstation size, please select a large first-class position to ensure that when hot-rolled plate is processed, because of the inherent characteristics of the plate, it is not suitable to adopt domestic high-Cr die, otherwise it is easy to wear, flaw and strip, etc. A series of defects are recommended to use imported high-speed tool steel as die material.