Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

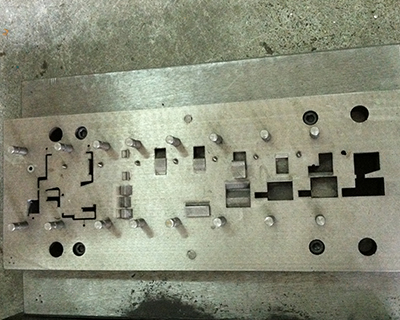

Detection of metal stamping parts was carried out, Dalian stamping manufacturers tell you.

Hardness test of stamping materials, its main purpose is to determine the extent of annealing the sheet metal stamping process is suitable for the purchase will be subsequently the stamping process of different types, different requirements of plate hardness level. For the detection of Aluminum Alloy plate stamping processing available webster hardness meter, material thickness is greater than 13mm can use the Barcol hardness meter, pure aluminum or low hardness Aluminum Alloy board should adopt the Barcol hardness meter. Hardness testing of hardware stamping parts by Rockwell hardness. Small, stamping parts with complex shapes, can be used to test the plane is very small, can not be detected by ordinary desktop Rockwell hardness tester.

Stamping processing including blanking, bending, deep drawing, forming and finishing processes. Stamping processing is the main materials of hot or cold (with cold based) metal strip material, such as carbon steel, alloy steel, spring steel, galvanized plate, tin plate, stainless steel plate, copper and copper alloy plate, aluminum plate and Aluminum Alloy etc.. PHP Series Portable Rockwell hardness tester is suitable for testing the hardness of stamping parts. Alloy stamping is the most commonly used in the field of metal processing, machinery parts manufacturing. Stamping processing is used to mold the metal plate with processing method of separation or forming. The application range is very wide.

In the stamping industry, sometimes called stamping sheet metal forming, but slightly different. The sheet forming refers to the use of plate, thin walled tube and wood as raw materials for plastic forming method is called sheet forming, the deformation direction of the plate is generally not considered. Market and technology level of our country because of the many stamping stamping plant belonging to the host plant, therefore, stamping Market is not perfect and sound. But small stamping parts market in some areas of the south is very mature. From the current situation, our country stamping market has the following questions:

Some of the production capacity of some host plant pile up in excess of requirement, stamping plant, put no, not holding. Most of the time a year production task is insufficient, non market behavior. Household appliances, electrical appliances stamping industry market competition. But the climate of international competitive enterprise is not much. Seriously study the stamping Market things no one. The stamping Market out of order. In the market condition, technology development limited, the whole industry is backward, in the overall level is low, many industries overcapacity, lack of high-grade technology. Technical progress is slow. Material technology, mould technology, lubrication technology and equipment level is low, can not meet the needs of the development of domestic production.

Through the understanding of the products, also can know the applications of various products such as spring compression spring is wide, basically covering the fields of machinery, hardware, electrical appliances etc..