Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

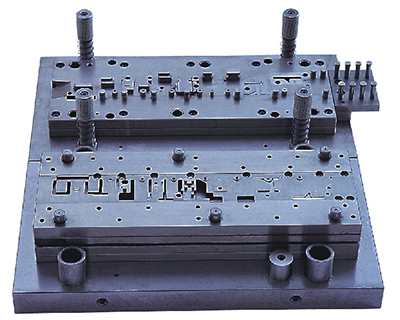

Stamping die is a special process equipment to process materials (metal or non-metal) into parts (or semi-finished products) in cold stamping, which is called cold stamping dies (commonly known as cold punching dies). Stamping is a pressure processing method that uses pressure on the press to make the material separate or plastic deformation at room temperature, so as to get the required parts.

In order to improve the strength of stamping die, the final process of stamping die manufacturing requires finishing the surface of the mold to eliminate the tiny cracks on the surface of the die, and prevent the stamping die from being damaged by the enlargement of the crack during the strong impact of the press. The general stamping dies are divided into concave die and punch, and the blanks are blanking through the die edge. Such as blanking, punching and other processes. The concrete process is as follows: when the press dies punching the stamping parts through the stamping die, the blank from the force produces the plastic deformation to the shape of the fracture to form.

The punch is directly exposed to the billet under the force of the press. The force of the blank is deformed, and the billet is bent under the action of torque. As the punch continues to press down, the blade of the die begins to cut into the blank. The plastic deformation occurs at the edge of the edge, and the deformation increases with the penetration of the edge.

The cutting mode of small cutting depth and large feed is widely used in the stamping die industry of Dalian to achieve efficient processing, but the market demand is required to further improve the processing efficiency. In view of this, Hitachi developed multiple cutting edge tool, and the coating can withstand the high cutting speed in the feed conditions. The design concept of multi blade large feed round corner cutter is based on the limited tool diameter, and according to the former edge number design method, it reduces the cutting edge size, but does not reduce the edge strength.