Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

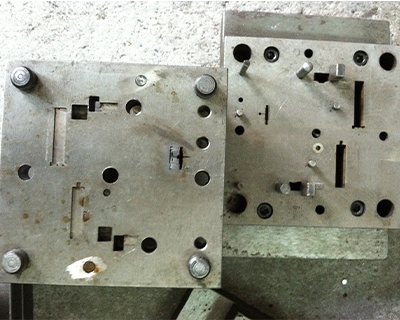

Under normal circumstances, Dalian mold processing has two parts: upper mold and lower mold. The steel plate is placed between the upper and lower die, and the material is formed under the action of the press. When the press is opened, the workpiece is determined by the shape of the mold or the corresponding waste is removed.

Small electronic connector, to the dashboard of a workpiece can die molding. Progressive die refers to a set of dies that automatically move the workpiece from one station to another and obtain the molding parts at the last station. The mould material is excellent and the hardness is high. The main material of the mould is made of high quality alloy steel, especially the die with high life. It is usually made of Crl2, CrWMn and other bainitic steel. Such steel from rough forging, processing to heat treatment are strict requirements.

Because the processing time is too long, the influence of the environmental temperature must also be considered. For example, when machining large dies on ordinary machine tools, when the ambient temperature changes 10 degrees Celsius, the temperature of the machine tool column will change at 6 DEG C, which leads to the change of the parallelism of the main angle plate 0.07mm. Therefore, the design of machine tools must take into account the effect of environmental temperature, and avoid environmental temperature affecting the accuracy of processing parts.

At present the main restricting factors of precision mold processing for accuracy requirements, processing level and technology level, technical level and mold fitter assembly manufacturing factory management level and production method. The main processing methods of the mold are three, namely: cutting, casting and special processing.

In the manufacture of the mould, not a process can meet the production requirements of all, in the use of a processing method can not meet the requirements, can be selected according to the production conditions and process requirements for flexible processing. So as to achieve the best effect of mold processing. The complexity of the plastic material determines the complexity of the injection molding process. The properties of plastic materials vary greatly due to different varieties, grades, manufacturers, and even batches.