Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

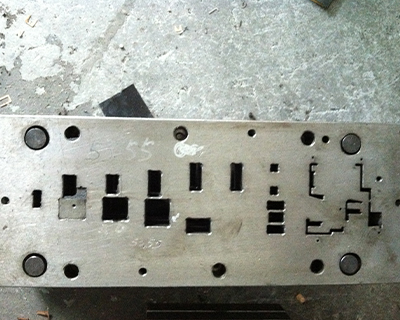

Future machinery parts processing industry will be more characteristic

Mold heat treatment process is divided into pre heat treatment and final heat treatment and auxiliary processes, pre heat treatment including annealing, normalizing, tempering and aging, this kind of heat treatment in rough machining and. The final heat treatment includes all kinds of quenching, tempering, carburizing and nitriding treatment, this kind of working process often before and after finishing. Dongguan mold processing auxiliary processes, including the work of the inspection, burr, cleaning and rust proof oil, etc.. Dalian stamping die quality requirements of the surface, are divided into processing stages, generally can be divided into rough machining, semi finishing and finishing three stages. Mainly in order to ensure the quality of processing; conducive to the rational use of equipment; facilitate the arrangement of heat treatment processes; and to facilitate the discovery of blank defects and so on. Usually in the processing process, with the processing surface accuracy is increased, there is bound to be a fine surface roughness, but with the surface roughness is worth reducing, processing costs and increase. Therefore, when determining the accuracy of the operator, the first to ensure that parts performance requirements, but also to consider the process conditions and parts manufacturing costs and other factors.

Die in the use of towel prone to the wear and tear of the different side of the core position, and some of the larger scratches, wear faster, this situation is particularly evident in the narrow rectangular mold. The stamping die should be silvery white and cold gas in vacuum carburizing after released, if released when the brightness component deterioration reasons may be: the furnace produced a larger leakage; vacuum quenching oil mixed with more air; cooling gas (e.g. nitrogen) is not high purity, which contains more oxygen cylinder oil; more into the vacuum quenching medium. Whether the stamping die design is reasonable is the basis of improving the durability of the stamping die. Therefore, the adverse conditions in stamping die design to product forming process to take effective measures to improve the durability of the stamping die design, such as hole punching die life is often manifested in the blanking punch holes on.