Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

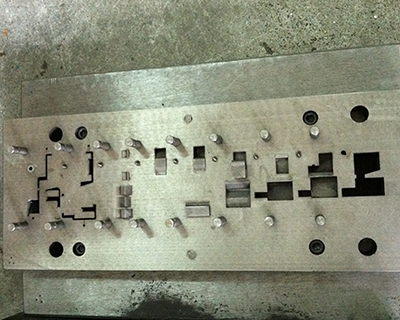

Dalian stamping die material what!

Stamping dieSteel, hard alloy, with the material of steel bonded carbide, zinc base alloy, low melting point alloy, aluminum bronze, polymer materials, and so on.

Now for the most part manufacturing stamping mold material is given priority to with steel, the types of commonly used mold working parts material: low carbon tool steel, alloy tool steel, high carbon high chromium or chromium in tool steel, medium carbon alloy steel, high speed steel, matrix steel and carbide, steel bonded carbide, etc.

When the stampingMould processingMaterial is hard or large deformation resistance, convex and concave die die should choose good abrasion resistance, high strength of the material.Deep drawing of stainless steel, aluminum bronze concave die can be used, because it has good tackiness resistance.The guide pin guide bush insist on wear resistance and good toughness, therefore more use mild steel surface carburizing and quenching.As another example, carbon tool steel hardenability is the main deficiency is poor, in die parts section size is larger, the center after quenching hardness is still low, but, when he worked in travel times a lot of pressure on the bed, because of its good resistance to impact has become advantages.For fixed plate, stripper plate parts, not only should have enough strength, but also for small deformation in the process of work.In addition, you can use cold treatment and cryogenic treatment, vacuum treatment and surface strengthening methods improve the performance of molded parts.For convex and concave die poor working conditions of cold extrusion die, should have enough stiffness, strength, toughness, wear resistance, such as die steel with better comprehensive mechanical properties, at the same time should have certain red hardness and thermal fatigue strength, etc.

1. Low alloy tool steel

Low alloy tool steel is on the basis of the carbon tool steel added just the right amount of alloy element.Compared with the carbon tool steel, reducing the quenching distortion and cracking tendency, improves the hardenability of steel, wearability is also better.Low alloy steel in the manufacture of moulds are CrWMn, 9 mn2v, 7 crsimnmov (code CH - 1), 6 crnisimnmov code (GD), etc.

Carbon tool steel 2.

Carbon tool steel in the mold is widely applied for T8A and T10A advantages for processing performance is good, price is cheap.But hardenability and red hardness, heat treatment deformation, bearing capacity is low.

3. The high carbon high chromium tool steels

Commonly used high carbon high chromium tool steels are Cr12 and Cr12MoV, Cr12Mo1V1 (code D2), they have good hardenability, hardenability and wear resistance, heat treatment deformation is small, high wear-resisting micro deformation of die steel, bearing capacity after high speed steel.But serious carbide segregation, must be repeated heading (axial upsetting, radial) pull pull to forging, to reduce the inhomogeneity of carbide, improve operational performance.

4. The substrate steel

On the basic elements of high speed steel adding small amounts of other elements, appropriately increase or decrease of carbon content, in order to improve the performance of the steel.The steel grade generally referred to as the substrate steel.Not only has the characteristic of high speed steel, they have a certain wear resistance and hardness, and fatigue strength and toughness are better than that of high speed steel, cold work die steel for high strength toughness, high speed steel material costs are lower.Is commonly used in the mold of the substrate steel has 6 cr4w3mo2vnb (code 65 nb), 7 cr7mo2v2si code (LD), 5 cr4mo3simnval (code 012 al), etc.

5. High carbon chromium in tool steels

Used in the mould of high carbon chromium steel Cr4W2MoV, Cr6WV, Cr5MoV, such as their low chromium content, less eutectic carbide, carbide uniform distribution, the heat treatment deformation, has good hardenability and dimensional stability.And the carbide segregation is relatively serious, compared to high carbon high chromium steel performance improved.

6. Hard alloy and steel bonded hard alloy

Carbide hardness and wear resistance is higher than any other types of steel, but the bending strength and toughness is poor.Used for mould cobalt tungsten carbide is class, the impact is small and require high wear resistance of the mold, can choose a lower cobalt content of carbide.The impact of mold, can choose containing a high percentage of cobalt cemented carbide.

Steel bonded carbide Iron powder to join a small amount of powder alloy elements (such as chromium, molybdenum, tungsten, vanadium, etc.) do adhesive, with titanium carbide and tungsten carbide hard phase, with the method of powder metallurgy sintering.Steel bonded carbide substrate is steel, overcome the carbide toughness is poorer, the shortcomings of processing difficulty, can be cutting, welding, forging and heat treatment.Steel bonded carbide containing a large amount of carbide, although the hardness and wear resistance is lower than hard alloy, but still higher than that of other steel, after quenching and tempering hardness can reach 68-68 HRC.

7. High speed steel

Among the highest in the high speed steel with steel hardness, abrasion resistance and compressive strength, high bearing capacity.Is commonly used in the mould have W18Cr4V (code 8-4-1) and tungsten content less W6Mo5 Cr4V2 (code 6-5-4, the brand for M2) and to improve the toughness and development of carbon vanadium high speed steel reduction 6 W6Mo5 Cr4V (code 6 w6 or low carbon M2).High speed steel is also need to change forging to improve the carbide distribution.

Dalian stamping mold factory is a professionalStamping parts, mould processing manufacturers, the company has a complete and scientific quality management system.If you have a need to mould processing, welcome to give us a call.www.dlhuashuo.com