Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Dalian starr's precision mould co., LTD

Touch people: manager xu

Telephone: 86-0411-88530055

Address: 1-4 Huaihe West Road, Jinzhou District, Dalian City, Liaoning Province

Web site: www.dlhuashuo.com

Development of laser manufacturing mold processing industry

1) laser indirect ChengMo process

(1) Selective Laser Sintering (Selective Laser Sintering, SLS) technology is the use of powder material forming, from the university of Texas at Austin in 1989 successfully developed, by using high strength step by step a CO2 Laser scanning Sintering material selectively powder to form a three-dimensional workpiece, the greatest advantages of SLS process is to select material widely.

(2) the three-dimensional light plastic (Stereo Lithography Apparatus, hereinafter referred to as SLA) technology is a step by step a uv laser beam scanning by using light curing glue method to form three-dimensional entity of artifacts.3 d Systems, companies in the United States in 1986 launched the commercialization of the SLA prototype 1.The SLA process of the highest machining precision can reach 0.05 mm.

(3) thin layer chip Manufacturing (Laminated Object Manufacturing, LOM) process using sheet material, such as paper, plastic film, Helisys company successfully developed in 1986 by the United States.Is obtained by CO2 laser cutting and material paste repeatedly, layered manufacturing entity artifacts.The characteristics of the LOM technology is suitable for manufacturing large workpiece, its precision is 0.1 mm.

The above three kinds of laser rapid prototyping technology due to the long development time, the technology is relatively mature, has been widely used both at home and abroad.But the method of 3 d workpiece cannot be used directly as a mold, the need for subsequent processing, so called indirect ChengMo laser technology.The main processing method has the following three types:

(1) rapid prototyping workpieces treated as a mold.LOM paper made of die processing via the surface directly instead of sand mold casting block;Or made of LOM paper mould processing via the surface directly used as a low melting point alloy mold, injection mold;Or lost wax casting wax mold forming die.SLS produced artifacts after infiltration copper, used as a metal mould.

(2) cavities using rapid prototyping parts as pouring silicone rubber, epoxy resin, polyurethane soft materials such as mold.

(3) using rapid prototyping system of a double hard mould.One is made of LOM paper base mold directly, after the surface of metal arc spraying and polishing research into metal mould;The other is a metal surface hardened backing mold.The hard mould can be used in sand mold casting, mold molding production, injection molding, and simple steel tensile modulus.

Made of the process of laser indirect ChengMo mould, avoiding the complicated mechanical machining, and can ensure the accuracy of the mold, also can greatly shorten the die making time, save costs, for complex shape precision mould, its advantage is particularly prominent.However, there still exist the die life is relatively short faults, so the laser indirect forming mould is suitable for small batch production.

2) laser direct ChengMo process

Selective Laser Melting (Selective Laser Melting, SLM) technique is in Selective Laser sintering (SLS) technology developed on the basis of.The characteristics of SLM for:

(1) molten metal parts fabricated with metallurgical combination of entities, relative density can reach almost 100%, greatly improve the performance of the metal parts.

(2) because of the laser spot diameter is small, so the power at a relatively low melting high melting point metal, with a single component of metal powder to produce the parts.

(3) the use of high power density, small light spot of laser beam machining, metal that has 0.1 mm size precision metal parts.

Selective laser melting (SLM) technique and laser engineered net shaping (LENS) technology for forming a good compactness, metallurgical bond organization and high precision, and has made the die life long features, has been paid attention to by the industry and academia, in foreign countries have introduced a variety of equipment prototype, some even started to commercialization;And the current domestic research and application is still in its infancy.

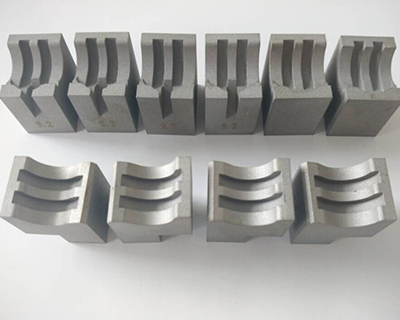

Dalian hua shuo petrochemical equipment co., LTD., in order to design and productionStamping dieSimple, forging die, injection mold, has a complete and scientific quality management system.Welcome friends from all walks of life come to visit, guidance and business negotiation.